From Powders to Final Products

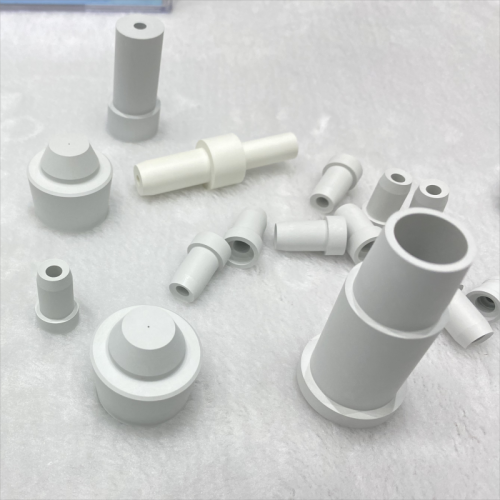

One-Stop Industrial Ceramic Solutions Provider

Revolutionizing Your Production Efficiency and Durability with Over 10+ Years of Specialization in Advanced Ceramics.

Get A Quote

Advanced Ceramic Materials

Silicon Carbide (SiSiC/SSiC)

Silicon Nitride (Si3N4)

Boron Carbide (B4C)

Zirconium Oxide (ZrO2)

Titanium Diboride (TiB2)

Aluminum Nitride (AlN)

![]()

other materials

Advanced Ceramic Material Parameters

| Technical Data | |||||

| Item | Unit | SISIC | NBSIC | RSIC | OSIC |

| SiC content | % | 85 | 75 | ≥99 | ≥90 |

| Free Silicon content | % | 15 | 0 | 0 | 0 |

| Max temperature of application | ℃ | 1380 | 1450 | 1620 | 1400 |

| Density | g/cm3 | ≥3.02 | 2 75-2 85 | 2.65-2.75 | 2.75-2.85 |

| Open porosity | % | <0.1 | 13-15 | 15-18 | 7-8 |

| Bending strength | Mpa | 250 (20℃) | 160 | 100 | / |

| Mpa | 280( 1200℃) | 180 | 120 | / | |

| Modulus of elasticity | Gpa | 330 (20℃) | 580 | 240 | / |

| Gpa | 300 (1200℃) | / | 200 | / | |

| Thermal conductivity (1200℃) | W/m.k | 45 | 19.6 | 36.6 | / |

| Coefficient of thermal expansion | K-1×10-5 | 4.5 | 4.7 | 4.69 | / |

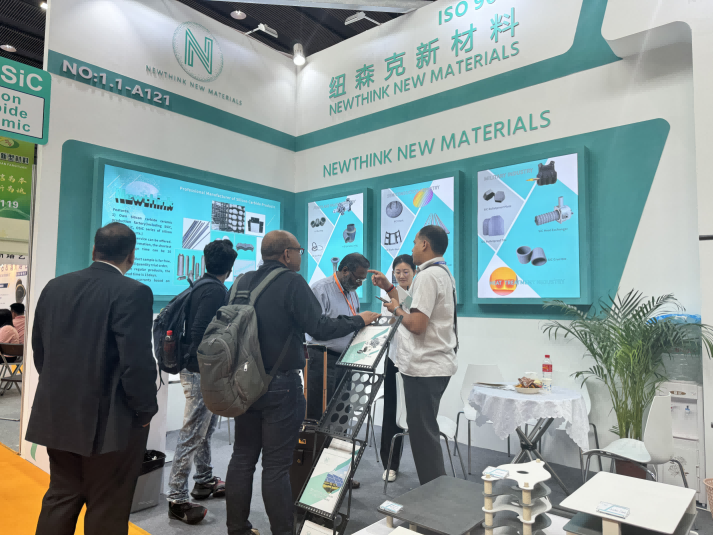

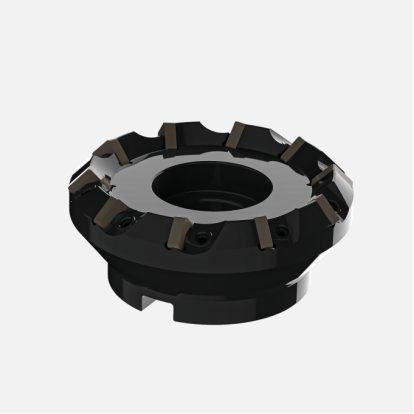

Hot-Selling Advanced Ceramic Products

Applications of Advanced Ceramics

Advanced industrial ceramics can enhance the efficiency, safety, and durability of production tools in various industrial sectors such as household ceramic production, heat treatment, aerospace, and photovoltaic semiconductors.

Aerospace Field

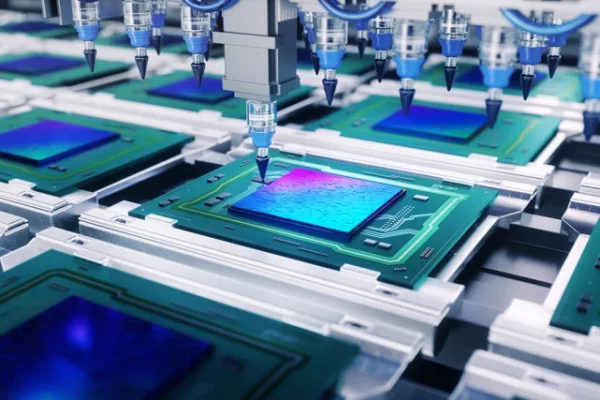

Semiconductor Field

Medical and Biological

Industrial Cutting Field

Heat Treatment Field

Photovoltaic Field

Kiln Furniture Field

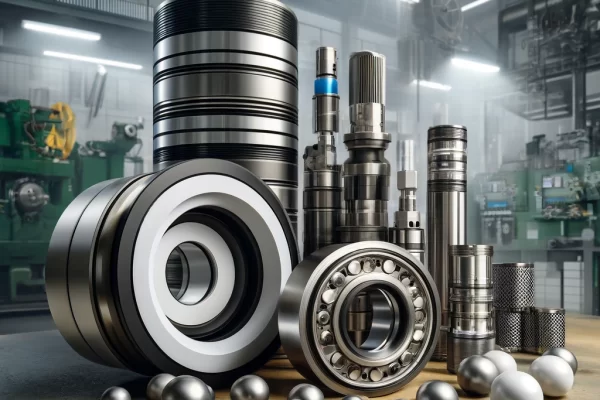

Mechanical Sealing

Military Field

Why Choose Us

We Will Provide Best Industrial Service For Your Business

-

Quality Control System -

Short delivery time -

Highly Professional Staff

-

Professional and Qualified -

Environmental Sensitivity -

Personalised solutions

Customer Interactions

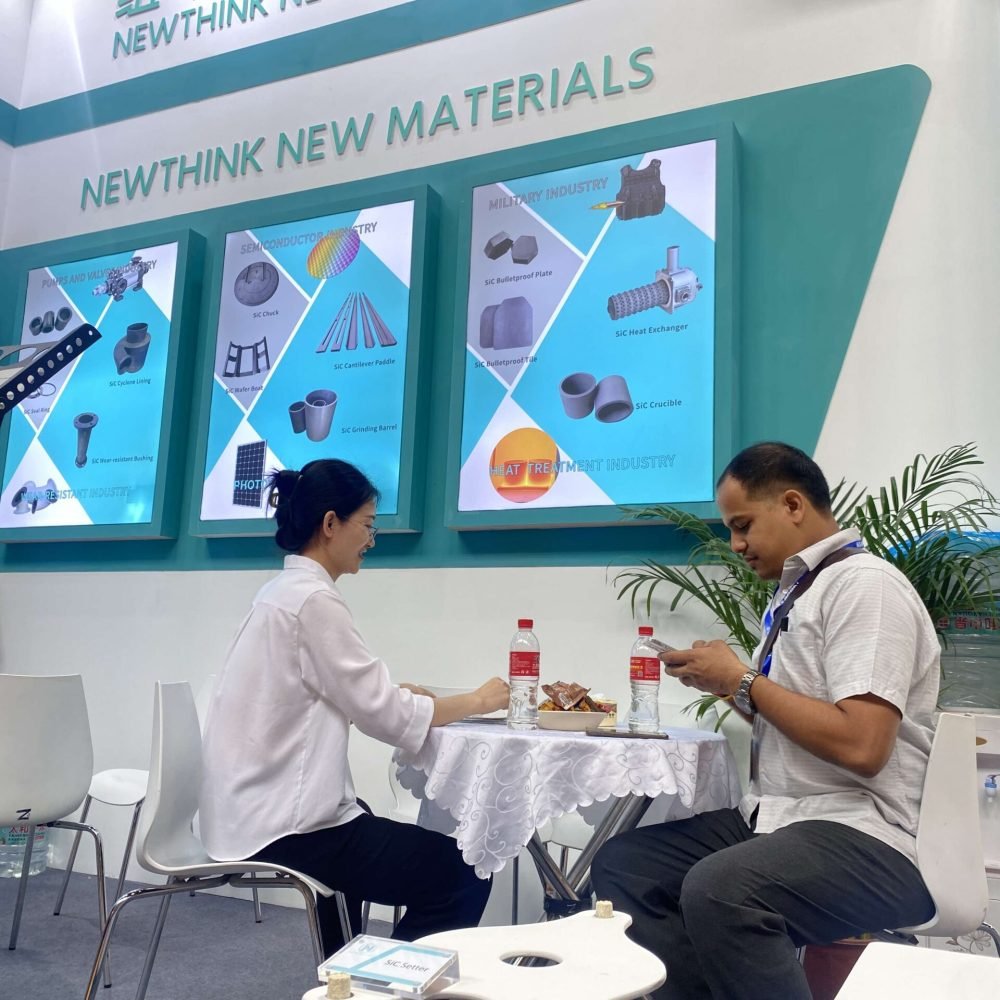

What’s Our Clients Say

I’ve been looking for silicon carbide products to solve my industrial problems, and after nearly 5 years of doing business with this company, we’ve become more than just business partners—we’re trusted friends. You can totally rely on this company.

Mustafa Yılmaz

Business

As a producer of daily-use ceramics, I can tell you this company’s advanced ceramics powder and products work great for us. Their materials always meet our needs, and their customer service is really helpful.

Ivan Petrov

Business

I’ve been to this company three times, and they always surprise me with their innovations. Their service and product quality just keep improving. It’s rare to find such a great partner.

Klaus Schneider

Business

Frequently Asked Questions

Advanced ceramics are high-performance materials with exceptional properties, including high strength, hardness, thermal resistance, and chemical stability. They are used in various industries such as aerospace, automotive, electronics, and medical devices for applications requiring durability and reliability under extreme conditions. advanced ceramics include materials like silicon carbide, alumina, zirconia, and boron nitride, among others.

Do you provide samples? Is it free?

Yes, our samples are free. Generally speaking, our free samples are based on existing molds. There are many similar situations. We will change our own molds to produce the products you need. In this case, the samples are free. If the product you provide is too complicated, and we need to make a custom-made mold, under this condition, a mold fee is required, because it is very expensive.

Under normal circumstances, we recommend T/T payment, but if this payment method is not suitable for you, you can consider Western Union, which has a lower fee. If your amount is small, you can also use PayPal to pay, which is more convenient.

What are the factors that affect price fluctuations?

Factors affecting price fluctuations generally include raw material prices, epidemics, domestic energy issues, etc., but we will quote you the most suitable price under the premise of ensuring quality.